ThermEx® Thermal Spray Coatings

ThermEx® Thermal Spray Coatings

ThermEx® Thermal Spray Coatings

Thermal Spray Coatings

ThermEx® Thermal Spray Coatings

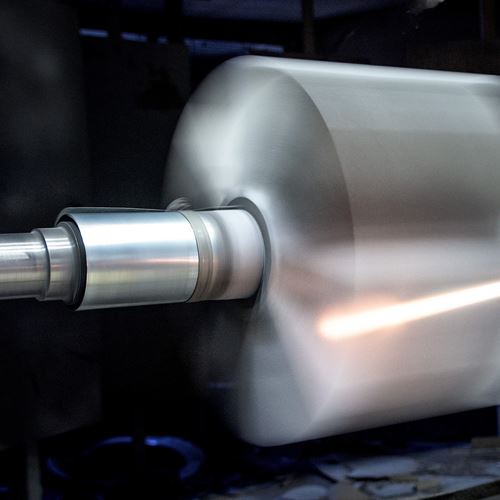

Exline, Inc.'s ThermEx® Thermal Spray Coating Systems restore worn components to "better than new" condition in less time and at a lower cost than replacement parts. Compare Thermal Spray to hard chrome plating.

Thermal sprayed parts

ThermEx® Thermal Spray Coatings

ThermEx® Thermal Spray Coating Systems can be used for all of these components:

- Bearing/Seal Areas

- Camshafts

- Compressor Crossheads

- Compressor Cylinders

- Compressor Pistons

- Compressor Rods

- Connecting Rod Eyes & Thrust

- Crankshafts

- Main Bearing Saddles

- Plug Valves

- Power Cylinders (ThermAlloy®)

- Power Cylinder Liners (ThermAlloy®)

- Power Pistons

- Turbocharger Components

Improve Performance & Service Life with thermal spray coatings

ThermEx® Thermal Spray

The following systems are utilized to improve performance and extend service life by Restoring Original Dimension, Improving Wear Resistance, Adding Corrosion Protection and Improved Lubrication:

- Combustion spray systems

- Twin Arc spray systems

- Plasma spray systems

- High Velocity Oxygen Fuel (HVOF) systems

ThermEx® Thermal Spray Coatings

Special Features

ThermEx® Thermal Spray Coating Systems coatings offer all of these features:

- Restores worn parts to original dimensions

- Improves wear resistance to prolong service life

- Adds corrosion protection

- Improves lubrication

- Provides an abradable surface creating near-zero running clearance

- Can be utilized to salvage production run under-sizings

- Alternative to hard chrome plating

ThermEx® Thermal Spray

Hundreds of Coating Options

Exline's ThermEx® Thermal Spray Coating Systems selects from hundreds of metallic and nonmetallic coating options and five spray options to achieve the protective characteristics most appropriate for your production part.

To help dissipate static discharge, plastic or fiberglass components are sprayed with conductive metals such as:

- Aluminun

- Copper

- Zinc

- Overview

- Machine Shop & Manufacturing Services

- ThermAlloy® Spray Coatings

- ThermEx® Thermal Spray Coatings

- Engine Starting Systems

- Engine Controls

- Protective Devices

- Field Machining Services

- Field Services Engine Repair

- Lubrication Equipment

-

AMOT

Valves and Sensors - Accessories

- Compressor Repair Services

- Field Services Engine and Compressor Repair

- Engine Services

- Engine Repair Services

- Compressor Services

- Compressor Repair & Manufacturing

- Engine & Compressor Monitoring & Controls

- Compressor Parts & Packing

- Parts

- Engine & Compressor Services Model

- Exline Express